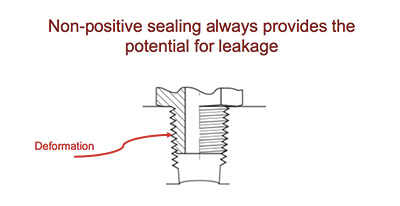

Tapered threads seal through deformation of the male and female thread. This non-positive sealing always provides the potential for leakage, so tapered threads are not recommended in high-pressure hydraulic systems.

They tend to exist on older systems and farm equipment but new systems should always be designed with parallel thread fittings, especially those with soft seals. In these seals, it is the O-ring that does the sealing — either straight against a flat surface, or inside of a boss. Here, a backup ring prevents the O-ring from being extruded. It’s held securely in place. These soft seals turn into a jelly-like consistency under pressure, filling in any gaps to prevent small contaminants from passing through.

As said, earlier, tapered threads only seal through deformation of the male and female threads. It is non-positive sealing — as you tighten the fitting, the male and female ends get tighter and tighter as one is pushed inside the other. It’s that force that pushes the thread peak against the thread crest of the female and closes those gaps. It crushes itself, and that’s what allows it to seal. Often, that still wouldn’t work, so pipe dope or Teflon tape is used to make the seal. Teflon tape actually can cause more leakage because the tape can fill that gap where the O-ring should be, or create spots of clearance between the O-ring and the boss that it’s supposed to rest within. Tape and pipe dope can also cause contamination if they corrode, break off and enter the system.

If you were to back out a tapered thread, it would become loose and would immediately have fluid that works its way around into the thread. When you also remove and replace an NPT thread, that deformation has already taken place. If there are any scratches or wearing that occur when an NPT fitting is taken out and put back in, the deformation is more difficult. It can’t happen a second time, so it provides a leak path.

If you are installing an NPT thread, make sure that you intend for it to be permanent. For example, if you have any hoses that will be replaced or removed on a regular basis, make sure that they’re either with a quick coupler, or the JIC type thread that can handle multiple disassembly and reassembly without any kind of leakage.

NPT threads are designed to have gaps that require a sealant to fill. Either pipe dope or thread tape. NTPF threads are designed to seal without added sealant, these threads seal by deformation of the mating material, most often used on brass low pressure fuel fittings. Tape or dope should never be used on parallel threads of an o-ring or flare fitting. There are sealants made expressly for sealing NPT threads of a high pressure hydraulic system, not to be confused with standard dope or tape for household plumbing.

I agree with the posting. What NPT threading has going for it is ease of assembly and looser tolerances. Fortunately it is often possible to use a straight tap and convert to straight threads. Cleaning up the chips is tedious but the final result is a joint that can be sealed with an O-ring jam nut and will not be leaking. And I have been able to use O-ring jam nuts on NPT connections, and they usually work fairly well.