By Josh Cosford, Contributing Editor Hose fittings, also known as hose ends, are critical components of hydraulic systems as they connect hoses to the system’s various fluid ports at the pumps, valves and actuators. There are two primary styles for hose end fittings: permanent crimped-on and field-serviceable screw-on, also known as reusable hose ends. This […]

Hydraulic

A review of hydraulic fittings and flanges

By Josh Cosford, Contributing Editor Improper selection or improper use of hoses, tubing, fittings, and assemblies can result in machine failures, leaks, personal injury, or even property damage if the failure is catastrophic. Understanding your plumbing standard chosen for your hydraulic system, and following the generally accepted installation standards reduces the chance of failure and […]

How can metric fittings provide hydraulic system leak protection?

By Josh Cosford, Contributing Editor We use metric fittings to connect and seal hydraulic valves, pumps or actuators to their respective plumbing in a metric-based circuit. They prevent leaks in hydraulic systems by providing a leak-free seal at the component’s fluid port. There are several types of metric fittings, including compression fittings, flare fittings, bite-type […]

What are the different standards for metric hydraulic fittings?

By Josh Cosford, Contributing Editor Several standards for metric hydraulic fittings exist, including DIN 2353, ISO 8434-1, ISO 6149-1, and BS EN ISO 12151-2. Each of these standards has its unique features and specifications, which are essential to know. They ensure that the fittings used in hydraulic systems meet the required standards and are compatible […]

How do you install metric fittings?

By Josh Cosford, Contributing Editor There are no secrets here, but installing metric hydraulic fittings depends on the type of fitting being used. You will need several tools to install them. Generally, you will need various wrenches, a hose cutter (if you’re making metric hose assemblies), a deburring tool, and, in some cases, thread sealant. […]

When should you use permanent hose fittings?

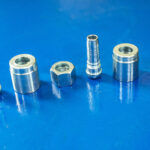

By Josh Cosford, Contributing Editor Hose fittings (also called hose ends) are crimped or threaded onto either end of a hydraulic hose assembly and provide the technician with an interface to connect the system’s conduits. Hose end fittings come in two primary styles; field-serviceable screw-on and permanent crimped-on. This article discusses when you should use […]

When should you use O-ring fittings?

By Josh Cosford, Contributing Editor Some objects are universal by their very nature, mattering not where you reside or if you’re part of a colonial legacy. No matter where you travel, a wheel is a wheel because it’s so absolutely perfect for the job that it leaves any other method of moving heavy objects obsolete. […]

How to find the right fittings for your hydraulic system

With a myriad of choices available, it is critical you fully understand your system needs before choosing your hydraulic fittings. Contributed by John Joyce, Marketing Director, Brennan Industries Inc. Making the shift to connections with elastomeric O-ring seals is the focus in today’s fluid power industry. But before following everyone’s lead, it’s important you understand […]

Air-Way Global Manufacturing celebrates 70th anniversary

This year, Air-Way Global Manufacturing is celebrating its 70th year of operations. The family-owned company, started in an old airplane hangar in Romeo, Mich., has since become the largest independent hydraulic fitting manufacturer in the United States. Since its start in 1950, Air-Way Global has thrived amongst its competitors, serving numerous industries and hundreds of […]

Extra tough hydraulic hose cover provides abrasion and ozone resistance

Gates introduces MEGASys MXT with XtraTuff Plus cover (MXT-XTP), a universally applicable hydraulic hose, featuring Gates’ patent-pending wire-braid technology. MXT-XTP offers all the benefits of Gates’ industry-leading MXT hose – compact size, light weight, flexibility and high performance – with added durability from the company’s proven, industry-leading XtraTuff Plus (XTP) cover. “Gates is known for […]