By Josh Cosford, Contributing Editor

Hose fittings, also known as hose ends, are critical components of hydraulic systems as they connect hoses to the system’s various fluid ports at the pumps, valves and actuators. There are two primary styles for hose end fittings: permanent crimped-on and field-serviceable screw-on, also known as reusable hose ends. This article discusses when to use reusable hose ends in your hydraulic system, but if you’d also like to learn more about when to use permanent hose fittings, find that article here.

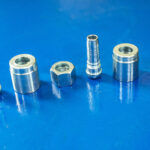

Reusable hose ends screw onto the hose and reinforcement and do not require crimping tools, making them easy to install in the field without specialized equipment. In addition, they offer flexibility in that they can be removed and reused multiple times, making them an ideal choice for applications where hoses require regular maintenance or replacement. Reusable hose ends come in various styles, including push-lock, barb, and compression fittings, offering flexibility in choosing the proper fitting for your application.

If you have an application that requires regular maintenance or replacement of hoses, reusable fittings are an excellent choice. They offer flexibility because they can be easily removed and reused multiple times, reducing downtime and replacement costs. They are also a good choice for applications where hoses require periodic adjustments or are subject to frequent movement where abrasion of the hose is unavoidable.

Reusable hose ends also offer a level of versatility in that they can be used with a range of hoses, including those with different diameters or materials. They are also available in a variety of materials, including brass and stainless steel, making them ideal for use in corrosive environments.

It is important to note that reusable hose ends require careful installation and proper torque to ensure a secure connection that prevents leaks. If the screw teeth are not matched ideally to the hose cover, the hose end may come off when pressurized, resulting in a failed connection. Conversely, overtightening may damage the hose and reinforcement, reducing the joint’s integrity and resulting in failure under pressure. Proper installation is critical to ensure a secure and reliable connection.

Field serviceable hose ends do not bite into the hose the same way crimped fittings do. The barb (the end that includes the threaded fitting) has an internal diameter larger than you’d see with crimped fittings because as you tighten the barb into the threaded sleeve, it’s the barb that pushes outward onto the hose. This compression effect locks the assembly in place, allowing the teeth on the sleeve to grab firmly on the hose reinforcement.

Care should be taken when selecting your hydraulic hose. It must be compatible with the acceptable size range for the chosen fitting assembly and specific to your machine’s application. For example, if your machine is outdoors in the hot sun, a hose rated for high temperature should absolutely be chosen. Because of the extra clearance and play inside the reusable fitting, it’s more likely to come apart when the outer cover and inner tube become soft with heat.

Reusable hose ends offer flexibility and versatility, making them an excellent choice for applications requiring regular maintenance or hose replacement. They are easy to install in the field without specialized equipment and can be reused multiple times, reducing downtime and replacement costs. However, proper installation and torque are critical to ensure a secure and leak-free connection.

Leave a Reply