At bauma this week, Danfoss Power Solutions has launched its new WalformConnect tube-forming machine. With an array of digital features, data tracking, and cloud connectivity, the WalformConnect machine enables simple and safe hydraulic tube forming within the Walform system — a leading cold forming metric tube fitting system — driving reliable performance and optimized production […]

Pipe and tube

What are the advantages of hydraulic tubing?

Tubing, when done well, is highly reliable and maintenance-free. The only time you change tube is typically when a modification or upgrade is done to the machine. Tubing resists motion or vibration that, although possibly transmitted, doesn’t cause it to shake or move the assembly itself. However, the inherent flexibility of hose permits chaffing, rubbing […]

Common considerations for hydraulic tubing

By Josh Cosford, Contributing Editor The metal tube assemblies used in hydraulic plumbing applications offer one of the most reliable methods to transfer fluid under pressure. Still, their factors for design and installation are sightly more complicated than hose assemblies, which are traditionally more popular. Mills make seamless tubing used for hydraulic systems by pushing […]

Parker’s High Performance Flange System gains new certification for marine applications

Parker Hannifin has announced that its mechanical flange system for machines and plants (with working pressures of up to 420 bar) — “HPF – Parker High Performance Flange System” — has gained DNV GL approval for marine applications. The DGUV approval certifies the use of Parker’s HPF in hydraulic systems for injection moulding machinery as […]

Making quick, safe connections at sea with non-weld flange systems

Using non-welded flange systems, such as Parker’s High Performance Flange connectors, reduces errors and saves hours on installation in mission-critical marine applications. Hydraulic high-pressure connections in the marine market must withstand harsh conditions, vibrations and other environmental impacts. Traditional welded connections do not always withstand these rigorous demands, and often require time-consuming and costly post-welding pipe […]

37 degree flaring and assembling machine for rigid tubing

New Unispeed USDFL 24/37 ES 6/18 flaring and assembling machine is allows for comfortable pre-assembly of rigid tubes of 06-18 mm with tight bends. It allows easy preassembling operations of DIN2353 rings and, with the addition of a dedicated steel block, can also be used for 37° flaring of hydraulic tubes up to 18 mm […]

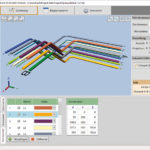

Updated software ensures production safety in tube processing

The high-tech engineering company transfluid from Schmallenberg has further developed its t project software. The two versions cover different areas of tube processing. The connection to CAD, BDE (Manufacturing Execution System) or ERP systems, to bending machines or bending robots makes the software flexible for each task. This way it is possible to test different […]

ZSi-Foster, an Ideal Tridon company, completes acquisition of Hydra-Zorb

ZSi-Foster Inc., an Ideal Tridon company, announced that it has completed the acquisition of Hydra-Zorb Co. Terms of the transaction were not disclosed. Headquartered in Auburn Hills, Mich., and founded in 1972, Hydra-Zorb provides pipe, hose, and tube clamping for the hydraulic, HVAC, plumbing, and refrigeration markets. Widely recognized for the invention of the cushioned […]

Mass customization comes to hydraulic tubing

Flexible manufacturing of hydraulic tubing assemblies has become an essential part of agricultural equipment production. Efficient and cost-effective manufacturing of agricultural and mobile equipment today depends on highly engineered production systems. And that holds not only for complete machines like tractors and combine harvesters, but also for essential subsystems like hydraulic tubing assemblies. transfluid Maschinenbau […]

transfluid establishes new U.S. subsidiary

transfluid Maschinenbau, based in Schmallenberg, Germany, has opened a new subsidiary in Greenville, S.C. The company manufactures tube bending and forming machines for hydraulics and other systems. The machines are sold worldwide, in a sector where being close to the customer and delivering quick service are increasingly valued. The U.S. is very important for transfluid, […]