When looking for connectors for your pneumatic systems, it is important to understand what type of connection is being made. Fittings can be used to connect pneumatic tube, pipe or hose and each connection requires specific fittings.

Pipe fittings, push-in fittings, barb adapters, compression fittings, and quick-connect fittings are some of the most common types available. They can be manufactured in plastic, brass, steel, stainless steel and other materials. It is critical the fitting and tubing or hose are compatible with each other. Other important considerations for fittings include pressure-holding capacity, ease of installation, size and weight, corrosion resistance and, of course, cost.

With hose barb terminations, the tubing is pushed over a barb slightly larger than the tube.

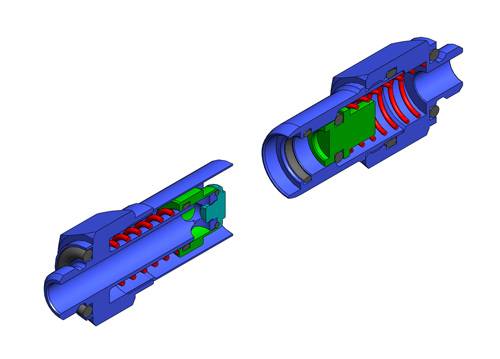

Compression fittings use a ferrule. This ferrule is slid over the tube to make the connection and then is secured by compressing the assembly together.

In push-to-connect fittings, the tubing is inserted into the fitting end. Push-to-connect are often quick-connect fittings, which offer easy connections and safe, dry-break release. They are available in plastic and all-metal, stainless steel designs for pneumatic applications.

I am a commercial diver. I want to build a custom manifold (1/4″ or 3/8″ fittings). the PSI would not exceed 225 lbs. It would consist of fittings and valves. I was looking at brass but, I would like your advise, since it would always be in water (fresh and salt) what material would you recommend? weight is a factor as well. Aluminum, Brass, stainless, plastic? NPT, flair, compression, push-in, barb? I can send a picture if it would help. Thank you