Before you select a hydraulic fitting, you must first determine if its threads will match the hose you have selected. Measuring and identifying the fittings is easily done but you must have the correct tools. These tools include ID/OD calipers and thread pitch gauges.

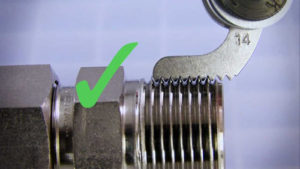

Using the thread pitch gauge, as seen in Figure 1, simply place the gauge teeth on the threads until a tight fit is found. Ensure that there is no gap between the teeth of the gauge and the fitting. If the fitting is not new or worn, you may have difficulty finding a match so it’s best to always use new fittings. Fitting manufacturers provide thread identification guides either in brochures or on their websites, so you simply need to match the thread measurement to the relevant charts.

To measure the thread’s outer diameter (or male thread), place the ID/OD caliper around the fitting threads for a snug fit, as shown in Figure 2. For the inner diameter (or female thread), insert the caliper into the fitting for the correct measurement and match to the manufacturer’s data charts.

You must also know whether your fitting is tapered or parallel, i.e. either at an angle or measuring the same width from one end of the threads to the other.

Understanding some of the most common connector types will help in identifying and measuring them in thread identification guides. NPTF (National Pipe Tapered Fuel) connectors are used in fluid power applications although not recommended. Other common designs are NPT, SAE J514 JIC/37°, SAE J1926 straight thread O-ring boss, SAE J512 45°, SAE J1453 O-ring face seal, ISO and DIN connectors, among others.

Where I can buy this caliper according to picture. I already have a thread guage.

Hello Jatupol – this caliper actually was supplied by Eaton Corp. so I suggest you contact your sales rep or distributor to see if they can help you out. Thank you for reading!