Stauff recently introduced a stud-welding system that simplifies the installation of clamps for hose, tubing, pipe and cable. The SWG Stud Welding System reportedly provides a fast and easy way to attach threaded studs to a machine or structure. The studs replace conventional weld plates, and are the base for mounting the company’s standard hose and pipe clamps, said Jeff Behling, president of Stauff Corp., Waldwick, N.J. The system can also be used for alternative fastening methods, such as for clamping belts, cable ties and corrugated cable-protection hoses, added Behling.

According to company officials, stud welding is often considered to be the most economical method for fastening components. Studs attach in about the quarter of the time needed to fasten weld plates. And because a stud gets welded to the substructure over its entire surface without any hollow areas, the result is a high-strength joint.

The SWG system includes an inverter and weld gun as well as weld studs, distance plates and related hardware, Behling explained. The inverter power supply operates at only 230 V, a lower voltage than is typical of many welding systems. As a result, it eliminates the need for heavy and expensive power cords. Current ranges from 100 to 650 A with stepless control. The compact unit measures 465 × 330 × 350 mm (18.3 × 13.0 × 13.8 in.) and weighs less than 20 kg (44 lb).

The hand-held weld gun includes a tripod for stability and a stud retainer. A user manually inserts a stud into the chuck and positions it onto the workpiece. Squeezing the trigger starts the welding process, which completes in 5 to 200 msec. Steel weld studs have M6 or ¼-20 UNC female threads and measure 11 mm (0.43 in.) in diameter and 14 mm (0.55 in.) high.

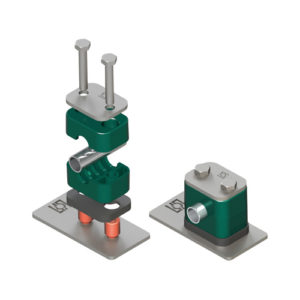

Distance plates are spacers that set the needed distance between studs and provide the necessary offset between the clamp bodies and substructure. Distance plates are made of polyamide, although alternative materials are available, and are 6 mm (0.24 in.) thick. Depending on the size, they have a single hole or two through-holes on centers ranging from 20 to 120 mm (0.79 to 4.72 in.), to accomodate various stud spacings.

Stauff clamps mount on the distance plates and fasten to the studs. They come in two halves in a range of sizes, and are made of thermoplastics, thermoplastic elastomers, aluminum and other optional materials. They include versions with: profiled inner sufaces for rigid pipes and tubes; smooth inner surfaces for flexible hoses and cables; elastomer inserts to reduce vibration and noise; and flame-retardant materials. Hardware for mounting clamps to studs includes cover plates, hex bolts and socket cap screws.

The Stud Welding System works without shielding gas or the need for ceramic ferrules. And the process ensures low thermal stress that minimizes material distortions. The ergonomic weld gun facilities streamlined handling and fast operations, requires only one-sided accessibility, and provides the flexiblity to work in any orientation—even overhead positions.

Stauff Corp.

www.stauff.com

Leave a Reply