Fluid Power World Contributing Editor Josh Cosford gave a webinar presentation on Proper Hose Assembly Guidelines. The transcript has been divided into an 8-part blog post series. The following excerpt from that webinar transcript is the fifth part of the series.

Fluid Power World Contributing Editor Josh Cosford gave a webinar presentation on Proper Hose Assembly Guidelines. The transcript has been divided into an 8-part blog post series. The following excerpt from that webinar transcript is the fifth part of the series.

Probably the most important when it comes to consideration of hydraulic hose is pressure. Without the capacity to resist pressure, hydraulic hose must use some cheap old garden hose and connect it to your hydraulic system. But pressure capacity in hydraulics is the defining criteria for hydraulic hose and pressure dictates construction. The fact that hose exist for hydraulic applications in a lot of ways it’s ideal to use tubing so you would bend tube or piping and it’d be permanent. They tend to last longer, but any kind of application in fluid power that requires any kind of motion between two arcing services, like a boom or a crane, or in some applications where you want to reduce vibration, hydraulic hose can be selected. How the hose is constructed fully dictates what pressure capacity it’ll have.

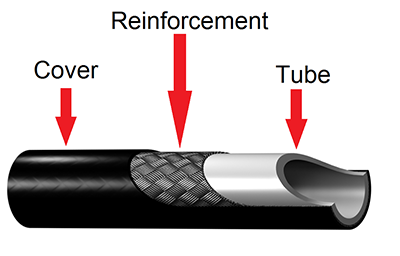

Pictured on the right is a general example of a slice of hydraulic hose. What we have here is the outer cover. Like I said, most times it’s made out of neoprene. It’s fairly abrasion resistant, fairly chemical resistant. It’s popular for a reason. This example has one layer of reinforcement. This is braided hose. You may have heard the term 1-wire hose, 2-wire, 4-wire, when you hear those terms to describe a type of hose, you generally have an idea of its pressure capacity. Say I just want 1-wire hose, depending on the size and diameter, that could play a part in how much pressure the hose can take, but this would be an example of a 1-wire hose.

Pictured on the right is a general example of a slice of hydraulic hose. What we have here is the outer cover. Like I said, most times it’s made out of neoprene. It’s fairly abrasion resistant, fairly chemical resistant. It’s popular for a reason. This example has one layer of reinforcement. This is braided hose. You may have heard the term 1-wire hose, 2-wire, 4-wire, when you hear those terms to describe a type of hose, you generally have an idea of its pressure capacity. Say I just want 1-wire hose, depending on the size and diameter, that could play a part in how much pressure the hose can take, but this would be an example of a 1-wire hose.

You have your outer cover, you have your reinforcement, which is a 1-wire in this case. You can see that it’s crisscross braided pattern, very flexible. Then you have your tube or your inner carcass and most often it’s nitrile, which is very resistant to oil, won’t breakdown. It’s a synthetic rubber. It’s good for a lot of different types of fluid and temperature ranges as well.

What we have pictured on the left is an example of a 2-wire braided hose. This particular example has the inner tube, the carcass on the inside, one single piece of that. By an outer braid another piece of tube or carcass and then another outer braid. Sometimes the wires can be wrapped directly on top of each other, each layer of wire, and then you would have your outside of your outer carcass. This is what you call 2-wire hose.

What we have pictured on the left is an example of a 2-wire braided hose. This particular example has the inner tube, the carcass on the inside, one single piece of that. By an outer braid another piece of tube or carcass and then another outer braid. Sometimes the wires can be wrapped directly on top of each other, each layer of wire, and then you would have your outside of your outer carcass. This is what you call 2-wire hose.

I don’t know if anybody has ever seen the inside of a hydraulic hose or worked on them, but you may have heard people use that kind of terminology. It’s pretty common; I’d say 90%, maybe even more, of the applications that I’ve worked on have been 2-wire hose. This particular 2-wire braided hose is generally pretty flexible. The way the crisscross pattern of wires work, it allows you to bend it either way without a lot of rigidity. I believe most Highflex hoses will be made from braided wire such as this.

It’s a good general purpose hose. If I were one person stocking a hydraulic hose in my own shop I would stock mostly 2-wire hose. It has good high pressure capacity. The diameter is pretty fair. The OD won’t be as small in a 1-wire hose but over most applications it’s good all-round choice.

Stepping up a notch, pictured below we have a 4-wire hose. This example is spiral wound hose. You have your tube that has one set of wires being wound, looks like clockwise or kind of clockwise depending on which way you’re looking at it, and you have another carcass and the wires of the next layer of spiral wire in the opposite direction. Then you have the inner carcass and then the opposite direction of wire again, another carcass and then opposite direction of wire again.

This is a very strong way of creating a hydraulic hose. When you get up to a 4-wire hose, pressure capacity starts to rise but you have the downside of a lot more rigidity. Larger diameter hoses require this type of construction, so if you’re talking 1½, 2-in. hose, if you want to have 3,000 psi pressure rating or more, you have to get away the braided hose and go to these spiral wound hoses. There’s no other way around it.

You want to go really extreme you can have construction made from 6-wire (pictured above). This one is similar as the other styles, except you have 6 layers of crisscross spiral wound wire, in this case, laid right on top of each other; there’s no separating carcasses between them.

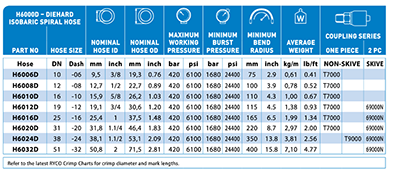

To the right is an example of a chart (courtesy of RYCO) for choosing a hydraulic hose. It would have their part number then dash sizes. In case anybody’s ever wondered what a dash size is, it’s really that number over 16 described in inches. For example, a -08 is 8 over 16, which is 1/2 in., or a -16, which is 16 over 16, which is 1 in. This chart is for a spiral wound hose, this would be a 4-wire application.

To the right is an example of a chart (courtesy of RYCO) for choosing a hydraulic hose. It would have their part number then dash sizes. In case anybody’s ever wondered what a dash size is, it’s really that number over 16 described in inches. For example, a -08 is 8 over 16, which is 1/2 in., or a -16, which is 16 over 16, which is 1 in. This chart is for a spiral wound hose, this would be a 4-wire application.

If you look at the maximum working pressure, that would be right around the middle there, every single one of these hoses, whether it’s 3/8, -06 all the way up to 1½, 2 in. is ready for rated for 6,100 psi. This is one of the advantages of a spiral wound hose, high burst pressure of course. If you look over at the bend radius, some of the larger hose have a bend radius. This is if you were to make a circle with the hose what would the smallest size circle you can make with this hose?

In this case, some of these larger sizes, like 2 in., would be 16-in. circles. To be honest, I wouldn’t want to bend a hose that big into a 16-in. circle to be pretty rigid. Also, we’re going to discuss the average weight of them. Bigger hoses, especially larger diameter, with more layers of wire will have more weight and that’s a given. Those are things to be considered for your application.

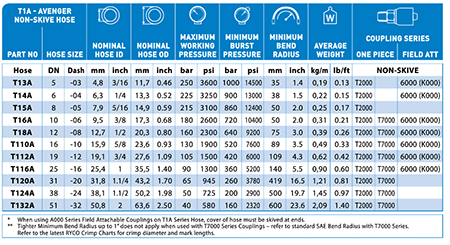

Now this chart to the left is for a 2-wire hose, I believe. This would be standard braided wire. Notice how the performance changes with the size of the hose. If you look at a -03 size, that’s pretty rare, 3/16. Typically, you see 1/4 in. as being a small hose. This one has a pressure rating of 3,250 psi. It’s important to consider that smaller diameter hoses, just by their nature, are able to resist higher pressures.

Now this chart to the left is for a 2-wire hose, I believe. This would be standard braided wire. Notice how the performance changes with the size of the hose. If you look at a -03 size, that’s pretty rare, 3/16. Typically, you see 1/4 in. as being a small hose. This one has a pressure rating of 3,250 psi. It’s important to consider that smaller diameter hoses, just by their nature, are able to resist higher pressures.

The construction allows them to have less force across any given perpendicular surface. I won’t get into why that is, but there’s less surface area for any given direction of force to push on. It has less ability to burst easily. As you go down the sizes here, if you go to say, 1/2 in., pressure all of a sudden drops to 2,300 psi. Not a whole lot bigger of a hose, it’s only 1/4 in. bigger but you lose 900 psi worth of working pressure.

Going down the line a little more you go down to the 2-in. hose, the -32. Now all of sudden this one is only good for 580 psi. This particular construction of hose you need to be careful. I’m sure it’s probably inexpensive and readily available, but you’re severely limited in what you can do with your hydraulic applications. Going over to the right a little more, go to the average weight. This is the weight per foot. If you guys remember what they were for the spiral wound hose, a 2-in. one per foot you’re talking 4.7 lb/ft of hose, but a 2-in. one of 1-wire hose is 1.4 lb/ft, quite interesting.

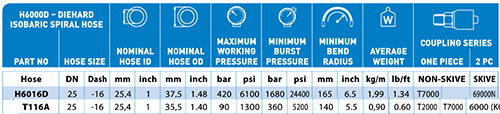

I did an amalgamated chart here (pictured below). There are 2 hoses: a 1-wire and a spiral wire. This is 1-wire braided versus a 4-wire spiral wound I believe. I created this chart to show them side-by-side. Both 1-in. hoses, but the bottom one being a spiral wound 1-wire. It’s only good for 1,300 psi. Whereas, as you may recall, all of the spiral wound hoses were good for 6,100 psi and that was regardless of size.

They’re good for pressure but if you go down the line here, you look a little bit, you can see the bend radius. You need 1-in. farther of bend radius on these spiral wound hose. You just can’t get in a tight radius. I should also mention that the spiral wound hose I selected, that T116A, I don’t think that was a HighFlex hose. If you had a HighFlex hose you might get half of that bend radius as well, so even further improved.

From a weight perspective you can see that the spiral hose is almost twice the mass per foot. Hydraulic hose can be heavy, especially as the diameter increases, but if you’re thinking about something like an excavator or pieces machinery that are already sensitive to load capacities, then you want to have the most amount of work out of the vehicle as possible and have less weight allocated to things like hydraulic hoses. These are important considerations.

Continue to part 6 here:

Proper Hose Assembly Guidelines, Part 6 – End Selection

Read the fourth part here:

Proper Hose Assembly Guidelines, Part 4 – Application Considerations

Read the third part here:

Proper Hose Assembly Guidelines, Part 3 – Effects of Temperature

Read the second part here:

Proper Hose Assembly Guidelines, Part 2 – STAMPED

Read the introduction here:

Proper Hose Assembly Guidelines – Introduction

Leave a Reply