Joyce Laird • Contributing Editor

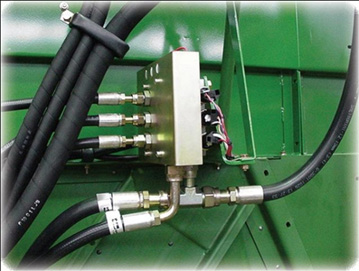

All hydraulic hoses should be visually inspected on a regular basis, said Robert J. Koehler, Sr. Training Specialist at Eaton Corporation. Inspection intervals should be determined by the frequency of use and/or the application of the hose.

The more the equipment is used, the more frequently it should be inspected. For example, if a machine is used on a daily basis, then it is recommended that the unit be inspected prior to use each day and/or shift. It is important to do a visual check, as opposed to touching the hose, because running a hand over a hose can lead to serious injury.

The more the equipment is used, the more frequently it should be inspected. For example, if a machine is used on a daily basis, then it is recommended that the unit be inspected prior to use each day and/or shift. It is important to do a visual check, as opposed to touching the hose, because running a hand over a hose can lead to serious injury.

You should complete the following steps for a visual inspection prior to operation, Koehler said. With power off, check the following:

- Check all hoses for leaks of any kind from the hose and/or fittings

- Check for damage to the cover, such as softening, abrasion, cracks, exposed reinforcement, blisters or bubbles

- Check for kinks, flat spots or a twist in the hose

“If any of these conditions are found, the hose should be removed from service. Also, a very important note: Never inspect hydraulic hoses with power on and always use proper PPE,” he added.

Leave a Reply