Although seemingly simple devices, protective plastic caps and plugs are critical in protecting hydraulic systems from dirt, moisture, corrosion and damage during manufacturing, shipping and storage.

Experts agree that 75 to 85% of all hydraulic system failures are a result of contaminants circulating within the hydraulic system. And while this contamination can occur during operation, a great deal of it is present in components before they are even installed on a machine. Typically reservoirs and plumbing have the highest built-in contamination levels when compared to the other components in the system. This is why protective caps and plugs are necessary.

They should be used during manufacture (including powder coating, painting, etc.), during assembly and packaging, shipping, storage and during machine shutdowns for repair or routine maintenance. They can prevent air-born dust and dirt, welding slag, foundry sand, machining chips, and other contaminants from entering a system through ports and fittings.

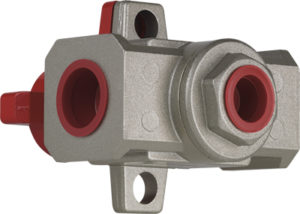

Available in a number of materials, including polyethylene, vinyl, silicone and rubber, they are designed to protect flared and flareless hydraulic fittings, SAE O-ring ports, JIC threads, BSP threads, NPT threads, Metric threads, quick-release couplings, hoses, SAE threads, flanges, valves, and more.

Caps and plugs can be manufactured with the following attributes: threaded, non-threaded, straight wall, tapered, tear-tab, pull-tab, metric, and masking. They are available in a variety of colors to match system needs.

Leave a Reply