Advances in hydraulic connection technology are again evolving within mobile machinery and tool/attachment design while positively impacting professional use. The increased demands of worksite productivity and efficiency by the expert user have challenged manufacturers of machines, attachments, and component suppliers with technological improvements. After all, “time is money.” This article focuses on the advances of the auto-dock system; What is it, what is causing this demand, and how is it impacting manufacturers and professionals?

Advances in hydraulic connection technology are again evolving within mobile machinery and tool/attachment design while positively impacting professional use. The increased demands of worksite productivity and efficiency by the expert user have challenged manufacturers of machines, attachments, and component suppliers with technological improvements. After all, “time is money.” This article focuses on the advances of the auto-dock system; What is it, what is causing this demand, and how is it impacting manufacturers and professionals?

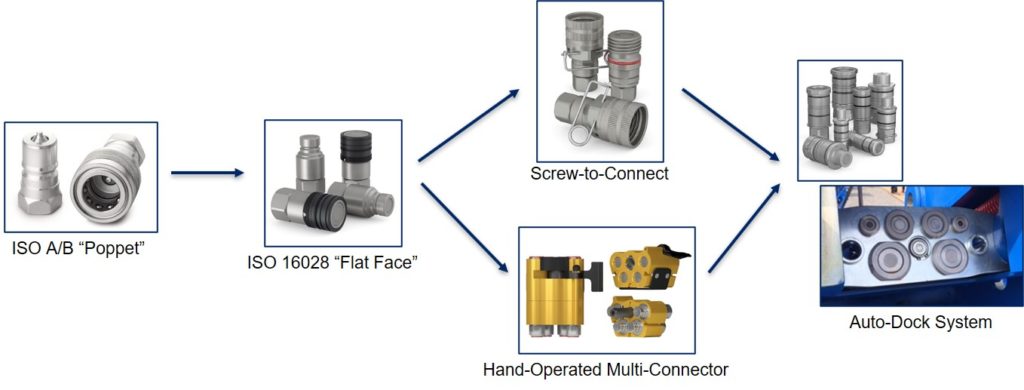

To better understand how auto-dock systems provide much-needed support, let’s review the evolution of hydraulic quick connects.

ISO A/B “Poppet” Quick Connect CouplingOften termed the general-purpose quick connect. Its basic design was only to offer an economical means to connect and disconnect hydraulic lines between machines and tools and attachments. This basic quick connect coupling has been in use for more than 50 years.

ISO 16028 “Flat Face” Quick Connect Coupling

Demand required the introduction of a no-spill/non-drip quick disconnect and easier “one-handed” connection — to eliminate oil loss and reduce contamination to the hydraulic system. Eventually, a residual pressure elimination nipple was introduced to ease concerns with difficulty in connecting attachments from thermal expansion.

Screw-to-Connect Coupling

The development of heavier duty machines increased concerns with vibration damage and surge flow issues. A screw-to-connect coupling allowed a quick break for heavier duty equipment while withstanding the difficult application effects of vibration and surge flows (helping to reduce and eliminate failures when using previous quick-connect designs).

Hand-Operated Multi-Connector System

As multiple hydraulic functions were incorporated into machinery, this increased the amount of hose routing connections. Challenges were made to reduce overall envelope size, eliminate cross-connection, residual pressure issues, and save overall connection and disconnection time. Hand-operated multi-connectors achieved all of these goals and opened up acceptance towards auto-connectors.

Fast Forward to 2020 — Today’s Auto-Dock System

This latest technological advance, an auto-dock system, allows a professional machine operator to change tools and attachments without leaving their cab. This is achieved by incorporating fit plates and blocks, using hydraulic cylinders and locking mechanisms, guide assistance, and electrical cab controls into a single configuration at the point between machinery and tools and attachments.

During connection or disconnection, an auto-dock system completely connects or disconnects all hydraulic lines, all electrical connections, any water lines, airlines, etc., simultaneously. Using this type of system greatly reduces downtime between tool/attachment changes to about 10-20 seconds overall when compared to the more traditional 5-10 minutes. An auto-dock system also helps eliminate issues related to cross-connection (user error of connecting/disconnecting all lines) and also helps eliminate “hanging components” that may be damaged in tight workplaces (like snagging a hose in close quarters on rebar or rubbing hoses against concrete).

Over the last 10+ years, a couple of familiar companies have offered aftermarket auto-dock systems for small and medium-sized machinery, mainly geared for small business implementation. As mobile machinery and tool/attachment manufacturers have realized the values of an auto-dock system (by customer demand for improved overall savings), they are beginning to include them with new model introductions.

Several larger OEM’s have also begun offering auto-dock systems bundled with standard tools/attachments. This provides professional users with a multi-function machine with greater capabilities and uses at each job site. Auto-dock systems are currently finding greater popularity in demolition and recycling industries (any site where cleanup is involved, and many tools/attachments are used). Still, the values can be gained in many mobile applications and industries.

As each manufacturer continues to develop capabilities using auto-dock systems, it will continue to revolutionize other mobile industries, similar to the influences caused by previous quick connect technologies. There are two common systems presently in use: horizontal and vertical connection. Thus far, the vertical connection system has been better received. It offers greater protection and improvements with the general lifespan on all auto-dock connections from dirt, debris, and other environmental conditions.

A key consideration for auto-dock systems is the frequency of tool/attachment changeouts. Suppose a professional machine operator has to frequently change out a specific group of tools/attachments each workday. In that case, this is a suitable target that should be evaluated for time loss reductions with the implementation of an auto-dock system. An important question often asked by fleet and site managers (for each job site) is how much equipment and personnel are required to get each job done.

If a machine typically uses the same 4-5 attachments or several machines share a group of tools/attachments (depending on the size of the job), it’s possible to increase the overall productively with an auto-dock system. It can free up valuable inventory and personnel for additional work sites.

Another element to auto-dock systems is the consistency of design and usage. This is especially important when it comes to “wear and tear” on components used in mobile machinery. Logically, an auto-dock system allows operators more consistent conditions between connection and disconnection change out needs. Removing unnecessary variables (including user-inconsistencies) helps improve the overall life of componentry in this connection point system. The addition of sensors and other safety aspects also helps redirect from reactive towards proactive maintenance, including a desired predictive maintenance schedule.

This technology shift is quickly bringing value to the mobile machinery industries. Once the investment is made, the professional fleet can quickly identify their “ROI.” It allows professional machine operators to work more effectively at each job site while allowing fleet or site managers to better plan and accommodate more jobs.

From a manufacturing standpoint, OEM’s can capitalize on advancing technology while meeting customer demands for improved productivity and efficiency. As auto-dock systems are used more often in mobile machinery industries, this technology should provide additional business opportunities compared to companies reluctant to adopt new ideas and principles.

Should you consider an auto-dock system?

1. Does your team or your customers have machines that frequently change out tool/attachments during each workday?

2. Has your team or your customers experienced issues related to a forgotten connection (i.e., hydraulic, electrical, water, air, etc.) during tool/attachment change outs?

3. Does your team or your customers often deal with damaged hose assemblies from “hanging hoses” in more confined work areas?

4. Has your fleet or site manager or your customers complained about effectively sharing machinery between job sites?

5. Does your team or your customers often dedicate specific tools/attachments to specific machines?

6. Would your team or your customers be interested in reducing maintenance costs between machines and tool/attachments?

7. Is your team or your customers weighing additional machines and tool/attachments purchases vs. trying to find ways to maximize usage with their existing fleet?

If you answered “yes” to one or more of these questions, it’s time to learn more about auto-dock system technology.

CEJN

cejn.com

Leave a Reply